Need help? We're here!

(888) 312-8812 Login SignupTop 3 Most Commonly Replaced Truck Parts

October 26, 2020

The trucking industry is among the country’s largest industries, and it has been growing immensely over the last few years. In 2019 alone, it moved about 11.84 billion tons of freight, generating an estimated $791.7 billion in revenue, according to American Trucking Associations, the largest national trade association for the trucking industry. It serves the American economy mainly by transporting goods—from manufacturing plants to retail distribution centers—across overland routes.

Apart from delivering goods, heavy duty trucks are also used for other purposes, such as towing, moving large appliances and furniture, and hauling. Because of these crucial tasks, these trucks are made tough, so they won’t break down easily. They are even equipped with large engines, strong transmissions, and a reliable braking system because they are designed to do heavy work, especially on job sites.

However, no matter how tough heavy duty trucks are, they too don’t last forever. While proper driving habits, regular inspections, and periodic maintenance can help extend the lifespan of various truck parts, some will need replacing eventually. And here are the top 3 most commonly replaced truck parts:

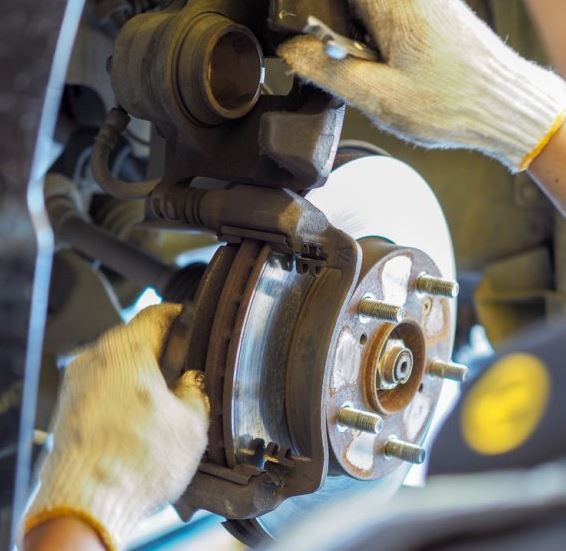

Brake Pads

Getting the truck to stop is as important as getting it started. A truck that won’t start may not put your safety at risk, but a vehicle that won’t stop is a rolling death trap. That is why before you hit the road, you have to make sure that all your brake system components, such as the brake pads, are in good working condition.

The brake pads are the ones that bear the brunt of the direct force when the brakes are applied. So, they are among the most commonly replaced parts in heavy duty vehicles. Although on most trucks they are expected to be replaced after three to five years, their lifespan actually depends on several factors, including your driving style, what kind of driving you do, how often you drive your vehicle, and whether or not you are involved in a lot of stop-and-go-traffic.

Stop-and-go traffic is terrible for the brake pads, and the same is true when you are fond of driving and stopping quickly. Avoid these at all costs, and be wary of the symptoms of bad brake pads. Squealing or screeching noises, deep metallic grinding and growling sound, and less than a quarter-inch thickness often indicate that your brake pads already need replacement.

Clutch

Drivers of manually transmitted trucks know all too well how crucial the job of the clutch is. It is the workhorse that allows any manual transmission vehicle to move from point A to point B. Every start, every stop, and every gear change means the clutch is doing its job well.

Because of their critical function, heavy duty clutches that are made from premium-grade materials and built to withstand harsh operating conditions are used on larger vehicles. But, just like any other truck component, these too are bound to get damaged or wear out over time. The good thing, though, is that they give you plenty of notice when they’re nearing the end of their service life, allowing you to get a replacement before they totally fail.

When the clutch starts to go bad, you will notice any of these signs: a squealing or chirping sound, a loud grinding noise, and a fast engine but a slow truck. You will also begin to notice that your truck can no longer be moved into gear mode; plus, it starts to get noisy when you are in neutral gear position but quiet when the clutch is held down.

Early detection of any of these bad clutch symptoms can help prevent accidents, steer clear of unnecessary breakdowns, and avoid costly downtime. So, make sure to include this transmission part in your regular truck maintenance checklist.

Tires

The sight of a trucker trying to replace one of his tires on the side of the highway is relatively common. That is because extensive driving time tends to wear the tire tread down faster. And when you add bad driving habits to the mix, a blown-out tire is like a ticking time bomb waiting to explode.

Heavy duty tires are responsible for your truck’s traction on the road, and they are expected to last well over 100,000 miles. While some trucks have tires that appear to be in usable condition even past this mileage, most of them warrant replacement tires earlier, especially those that are used excessively, carry lots of loads, and drive on unpaved roads frequently.

So, how do you know if it’s time to replace your truck’s tires? The first and easiest way to check if your truck already needs new tires is to check the tire tread. The tread is the part of the tire made from rubber that makes contact with the road. It deteriorates over time, and it starts to become thin, making the tire more susceptible to punctures, which can lead to sudden blowouts.

Cracks, uneven wear, and bulges are also indicators of a bad tire. These could mean that something is wrong with your alignment or your tire is on its way out. Either way, you need to have the tire checked and replace it if necessary.

To maximize the life of your tires, make sure to check them regularly. Take note that ten years is the maximum life of any tire truck tire from its manufacture date. When the tire goes past that, replace it even if it appears to be in usable condition and has not worn down to the tread indicator. Knowing these top three most commonly replaced truck parts can help you plan your replacement schedule well. When it’s time to get new brake pads and clutch, don’t go searching anywhere else. FinditParts carries a huge selection of heavy duty brake pads, clutch, and tire repair products for your servicing and maintenance needs. We offer these products at competitive prices with fast, reliable shipping guaranteed. Feel free to browse our online catalog to find the exact part that you need.